Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SPJG-008

Transportation:Ocean,Land,Air,Express

Place of Origin:China

This component is made of silver metal sheet with a smooth surface and metallic sheen. It has an irregular rectangular outline with precisely machined edges and several protrusions and slots; There are complex slots and through holes distributed...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SPJG-007

Transportation:Ocean,Land,Air,Express

Place of Origin:China

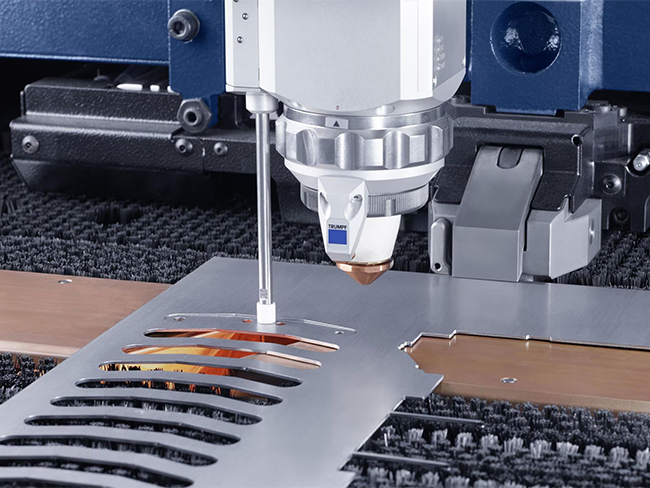

一、Advantages Non-contact Processing Laser cutting process, the laser beam and the material is not in direct contact, to avoid the traditional mechanical processing of tool wear, deformation and other issues, will not produce mechanical stress on the...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SPJG-006

Transportation:Ocean,Land,Air,Express

Place of Origin:China

一、Advantages Non-contact Processing Laser cutting process, the laser beam and the material is not in direct contact, to avoid the traditional mechanical processing of tool wear, deformation and other issues, will not produce mechanical stress on the...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SPJG-005

Transportation:Ocean,Land,Air,Express

Place of Origin:China

一、Equipment Capacity Numerical Control System Modern laser cutting equipment is equipped with advanced numerical control system, which can realize automated operation, precisely control the movement trajectory of laser beam through programming...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SPJG-003

Transportation:Ocean,Land,Air,Express

Place of Origin:China

一、Process Flow Drawing Design Customers provide design drawings or conceptual plans, technicians use CAD, CAM and other software to optimize the drawings and programming, the design will be converted into laser cutting equipment recognizable...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SPJG-001

Transportation:Ocean,Land,Air,Express

Place of Origin:China

一、Key Advantages High Precision Machining Precision Laser Cutting achieves a minimum kerf width of 0.1mm, ideal for intricate parts. Non-Contact Process Laser cutting belongs to non-contact processing, avoiding material deformation, especially...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SPJG-002

Transportation:Ocean,Land,Air,Express

Place of Origin:China

一、 Materials Aluminum Alloy With low density, high strength, corrosion resistance and other characteristics, it is widely used in automobile manufacturing, electronic products and other fields. When laser cutting aluminum alloy, it can effectively...

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.