Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Min. Order:1

This drone rotor support is made of die-cast aluminum as substrate and is part of sand casting, which is manufactured by Dongguan Shengpeng Precision Technology Co., Ltd. The central circular base is equipped with positioning holes and passage holes...

Min. Order:1

Sand Casting Parts is an intelligent door lock buckle made of die cast aluminum as the base material.The general construction is a long asymmetrical strip with a circular fastening with a left cut, can be strongly arranged using the cylindrical...

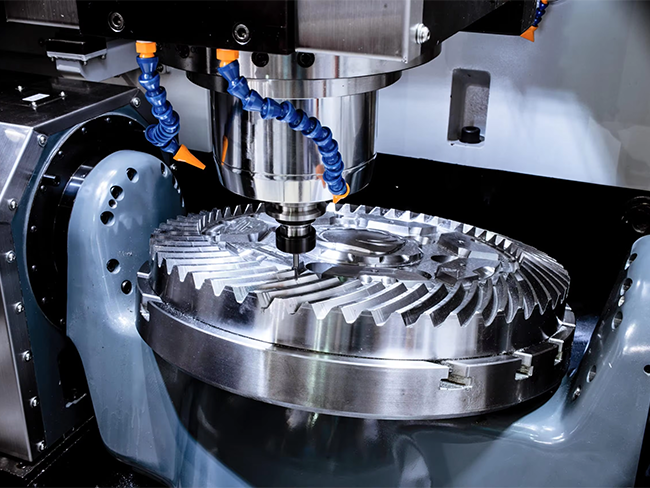

Sand casting is a traditional casting process that uses molding sand (such as quartz sand or specialty sands) mixed with a binder (clay, resin, etc.) as the primary molding material. Metal forming is achieved by constructing sand molds. Its core principle involves using sand particles to create a cavity that holds molten metal. After the molten metal cools and solidifies, the sand mold is broken apart to remove the casting. As the oldest and most widely applied casting method, sand casting accommodates cast iron, cast steel, and various non-ferrous metals. It produces the vast majority of metal components—ranging from large engine blocks to small hardware parts—making it an indispensable foundational technology in modern manufacturing.

二、Process Flow of Sand Casting

1. Pattern Making

The pattern, commonly known as a “wooden pattern” or “mold,” is a physical object resembling the final casting's shape and dimensions (accounting for metal cooling shrinkage). Traditionally made from wood (hence the name wooden pattern), it can also be crafted from metal, plastic, or resin.

2. Molding

This is the most critical step. The pattern is placed into a frame called a “molding box,” which is then filled with molding sand and compacted.

Molding sand is not ordinary sand but a mixture of silica sand, binders (such as clay or resin), water, and other additives. It must possess sufficient strength, permeability, and plasticity.

After molding, the sand box is split open, and the pattern is carefully removed, leaving a perfect cavity in the sand box. Sand cores, which form internal cavities, are often also made and placed in designated positions within the cavity.

3. Mold Assembly

The prepared upper and lower sand boxes, along with any sand cores, are precisely assembled together to form a complete mold ready for pouring. Precise alignment of the upper and lower boxes is essential to prevent misalignment defects.

4. Pouring

Molten metal is poured through the pouring system (gating system, sprue, etc.) into the assembled mold until the entire cavity is filled.

5. Shakeout & Cleaning

Cooling: Allow the molten metal within the mold to cool and solidify completely.

Shakeout: Break the sand box using vibration, tapping, or similar methods to remove the partially formed casting (still covered with sand at this stage).

Cleaning: Remove the casting's gating system, risers, flash, and burrs. Perform sandblasting to eliminate residual surface sand particles, yielding the final casting.

三、The success of sand casting relies on several key characteristics of the molding sand:

Refractoriness: Sand (primarily SiO₂) possesses an extremely high melting point, capable of withstanding molten metal temperatures exceeding 1500°C without melting.

Permeability: The minute gaps between sand grains allow air and gases within the mold cavity and cores to escape smoothly during pouring, preventing porosity in the casting.

Plasticity: Sand mixed with binder and water can be compacted and retain the shape imposed upon it.

Crumbling: After the casting solidifies and cools, the sand mold easily breaks apart and separates, facilitating casting removal.

What is Sand Casting

Applications of Sand Casting

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.