Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SP-007

Transportation:Ocean,Land,Air,Express

Place of Origin:China

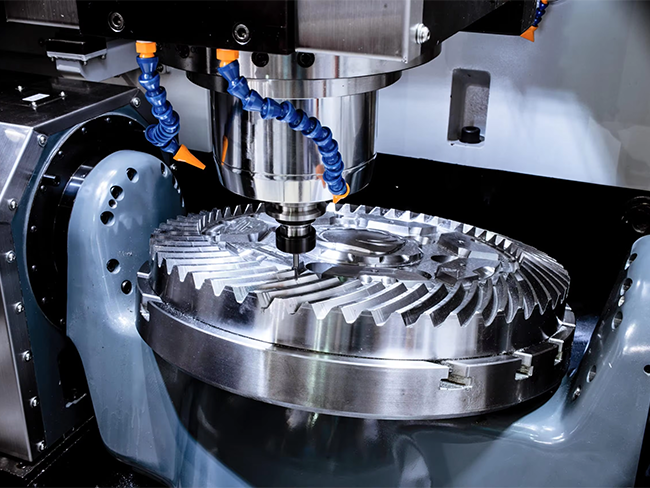

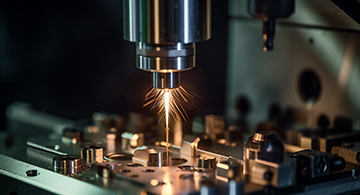

一、 Overview of CNC milling technology CNC milling, as the core processing technology of modern manufacturing, is profoundly changing the face of traditional mechanical processing. This technology converts design drawings into precise machining...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SP-006

Transportation:Ocean,Land,Air,Express

Place of Origin:China

CNC Milling is a precision milling technology controlled by a computer program. In the process of CNC milling, the cutting tool under computer control in accordance with the preset program on the workpiece for precise cutting, can process a variety...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SP-005

Transportation:Ocean,Land,Air,Express

Place of Origin:China

Dongguan Shengpeng Precision Technology Co., Ltd. is an enterprise specializing in high-end precision parts CNC machining services. We provide CNC milling, CNC turning, laser cutting, sheet metal bending and welding, casting molds and other one-stop...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SP-004

Transportation:Ocean,Land,Air,Express

Place of Origin:China

Dongguan Shengpeng Precision Technology Co., Ltd. is an enterprise specializing in high-end precision parts CNC machining services. We provide CNC milling, CNC turning, laser cutting, sheet metal bending and welding, casting molds and other one-stop...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SP-003

Transportation:Ocean,Land,Air,Express

Place of Origin:China

Dongguan Shengpeng Precision Technology Co.Ltd. is a professional enterprise engaged in high-endprecision parts CNC processing services, mainly engaged in OEM, ODM,CNC Milling, CNC Turning, Laser Cutting, Sheet Metal Bending, Sheet Metal Welding,...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SP-002

Transportation:Ocean,Land,Air,Express

Place of Origin:China

Dongguan Shengpeng Precision Technology Co.Ltd. is a professional enterprise engaged in high-endprecision parts CNC processing services, mainly engaged in OEM, ODM, CNC Milling, CNC Turning, Laser Cutting, Sheet Metal Bending, Sheet Metal Welding,...

Brand:SP-MFG

Min. Order:1 Piece/Pieces

Model No:SP-001

Transportation:Ocean,Land,Air,Express

Place of Origin:China

一、Key Advantages √High Precision Machining Our High Precision CNC Milling maintains tolerances within ±0.01mm, ideal for medical and optical components. √Complex Geometry Machining With 5-Axis CNC Milling technology, we can machine intricate...

Applications of CNC Milling

FAQ

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.